Parts Gallery

Industries from automotive and aeronautics to consumer products and medical devices use parts made from powder metal. These parts can be manufactured from a variety of processes and materials and range in size from less than a gram to 2.5 kilos (5 pounds). Examples include fuel injector and turbo charger parts, bevel gears, ABS rings, and large sprockets.

Here are some of the parts PMT has facilitated. Note that some illustrations have been changed slightly for confidentiality reasons.

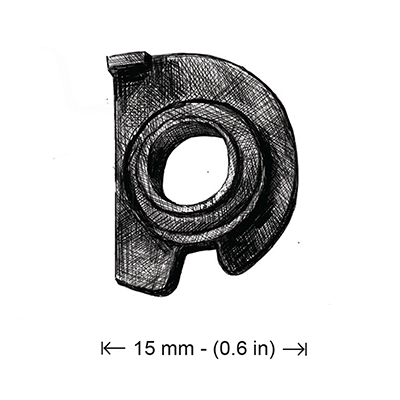

Two parts were consolidated into one in the design of this high-volume, electro-mechanical lever. Companies had been unsuccessfully trying to use metal injection molding (MIM) to produce this complex, miniature part for 10 years. PMT was able to frame the challenge and get the right people together to solve it. Read Case Study #1.

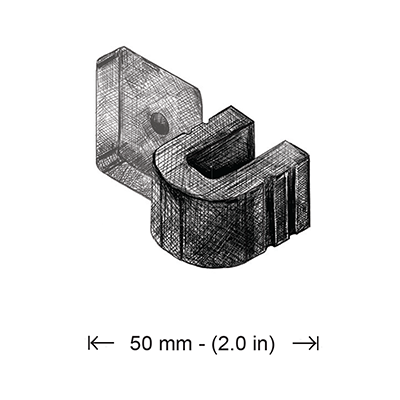

An account was scaling up and needed to reduce costs. During a design review, PMT was able to identify this complex-shaped small mechanical powder metal part. The powder metallurgy process selected met the account’s cost targets and PMT was able to bring to the table a manufacturer capable of producing the part. The account saved 50% or more by utilizing powder metal to make the part, for use in an electric vehicle. Read Case Study #2.

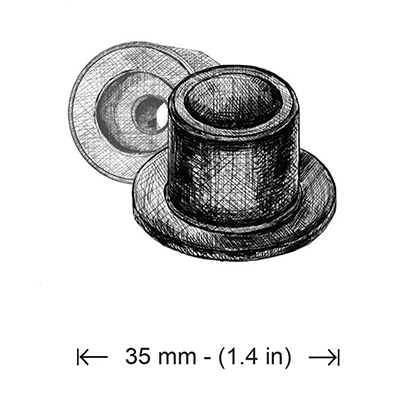

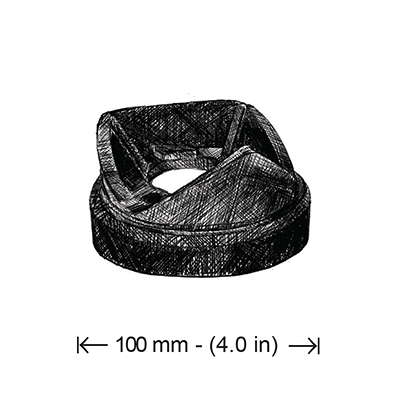

A powder metal manufacturer had some open space on presses, a common issue in this industry. PMT was able to identify this mechanical part used in the automotive industry, which was a fit with the company’s presses and helped it fill idle capacity, a big value-add. Read Case Study #3.

This mechanical part, used in sports medicine, replaces six parts traditionally used for this application. Thanks to PMT’s technical expertise and network of contacts, it was able to design this part for PM manufacture, on-site and in real time, something sales reps cannot do. Read Case Study #4.

PMT sat in on the design review of an automotive assembly and helped create this revolutionary design of a powder metal part for a sub-contractor. The application pushed PM technology as far as it could go, and even a little further, but PMT’s knowledge and creativity made it work. Read Case Study #5.

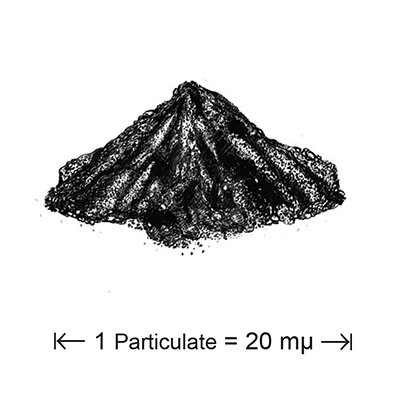

PMT brought a manufacturer of high-purity powder new customers and new revenue. It was able to think creatively and use a broad-brush approach to come up with new applications for the manufacturer’s unique product, thanks to its knowledge of the industry and network of contacts. Read Case Study #6.